Products

PVC 、 PVG

Whole core flame retardant conveyor belt

Keywords: mine conveyor belt, flame retardant, anti-static

Structural features:

Skeleton material is a dense whole formed by fully impregnating PVC paste resin with a core and then plasticizing it. It is covered with PVC or PVG wear-resistant layers on top and bottom, and has high strength, wear resistance, tear resistance, flame retardancy, anti-static and other characteristics. It is mainly used for material transportation in flammable and explosive places such as coal mines and warehouses. This product complies with the MT914 standard for fabric core flame retardant conveyor belts used in coal mines. High strength whole core flame retardant belts can replace steel wire rope core conveyor belts, but have lower operating costs and higher efficiency.

Performance characteristics:

1. Good flame retardant and anti-static performance, safer to use. The product is a fully impregnated, flame-retardant, and anti-static paste resin woven strip core that is high-temperature plasticized. It is then covered with a flame-retardant and anti-static thermoplastic elastomer transition layer and cover layer through an extruder, dynamic vulcanization, and has excellent flame-retardant and anti-static properties. Its indicators are superior to those of existing technology products and the specified values of MT914 standard, providing a guarantee for the safe transportation of coal underground in coal mines.

2. Low halogen content and smoke generation can prevent secondary disasters and environmental pollution.

3. Low rolling resistance, saving energy consumption during operation. By optimizing the formula and process, the loss factor of the covering layer (tan δ value at 60 ℃) has been significantly reduced, reducing the rolling resistance of the conveyor belt and thus significantly reducing the energy consumption during the operation of the conveyor belt.

4. Impact resistant, tear resistant, and scratch resistant. Due to the fact that the skeleton of this product is woven as a whole with a core, the full thickness tensile strength in both radial and latitudinal directions is high, making it impact resistant, scratch resistant, and impact resistant, without longitudinal tearing.

5. Good flexibility, allowing for smaller bending radii. Not easily delaminated.

6. Strong resistance to cold, moisture, water, and harsh industrial and mining conditions.

7. The bonding strength between the transition layer, skeleton layer, and cover layer is high, without foaming or delamination.

8. Thick covering layer, good wear resistance, and long service life.

9. There are many specifications and models, with a wide range of choices. The strength of this product can range from 680S to 3400S, and the width can range from 650mm to 2000mm. Users can choose different strength grades and widths of conveyor belts according to the actual load situation.

10. Easy installation and maintenance, high efficiency of use. This product can use both vulcanized joints and quick belt buckle links, with low joint workload and high joint efficiency.

11. High degree of intelligence

Electronic chips can be implanted in the belt core to achieve the intelligence of the conveyor belt.

Model and specifications:

The product models can be divided into 680S, 800S, 1000S, 1250S, 1400S, 1600S, 1800S, 2000S, 2240S, 2500S, 2800S, 3100S, and 3400S according to the longitudinal overall tensile strength of the flame retardant tape.

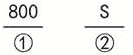

Model example:

1. The overall longitudinal tensile strength of the flame retardant tape is 800N/mm

2. Indicating flame retardancy and anti-static properties

Product Case

Application Cases

Application Cases

Application Cases

Application Cases

Product Consulting

Address: 157 Huaihai East Road, Huaibei Economic Development Zone, Anhui Province

Company Fax:86-561-3022135

Electronic E-mail:ahzyjd@163.com

WeChat Public Number